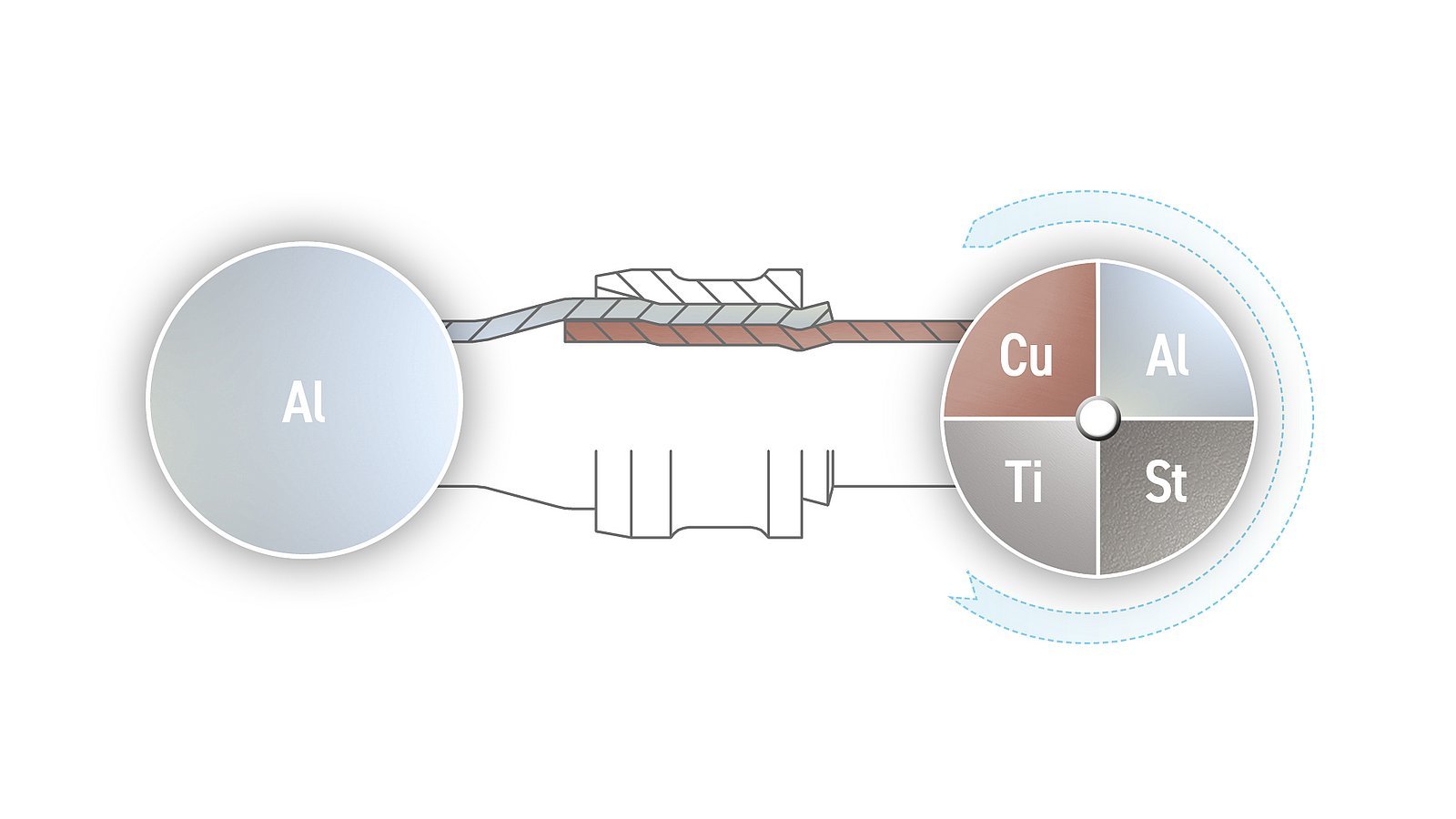

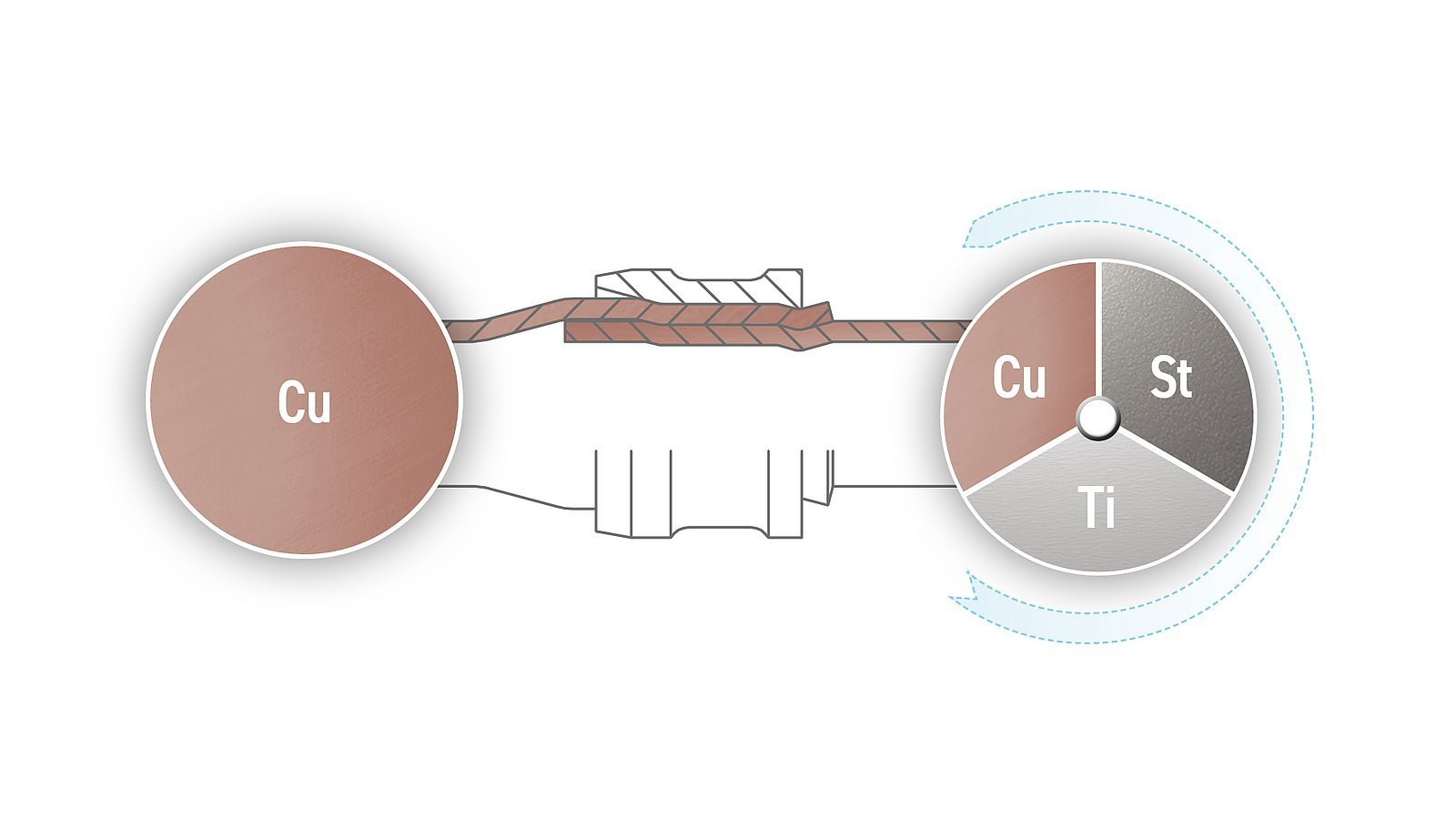

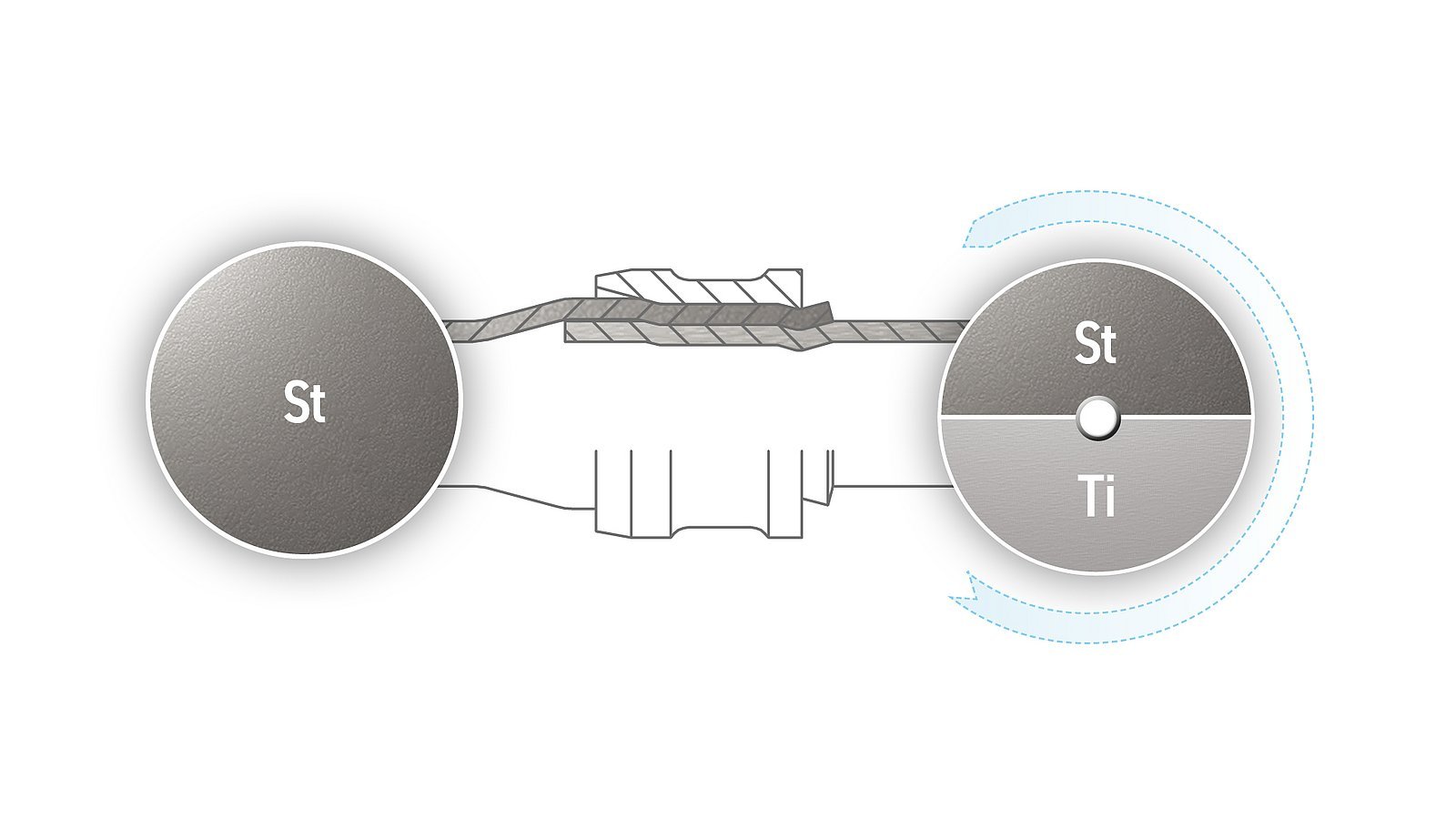

The LOKRING® Single Ring technology is a method for connecting metallic refrigerant lines without brazing so that they are permanent and hermetically sealed. For this purpose, VULKAN constructs customised LOKRING tube connectors for any application based on the tube materials, dimensions and tolerances and the associated assembly tools.

Areas of Application for LOKRING SINGLE RING-Technology

The primary area of application is the manufacture of the refrigerant circuit in the series production of refrigerators and freezers. There are other applications for the manufacture of evaporators for automotive air-conditioning systems, for heat exchangers in refrigeration and air-conditioning technology (e.g. manufacture of heat pumps) or with the serial installation of refrigeration and air-conditioning technology (e.g. air-conditioning for buses).

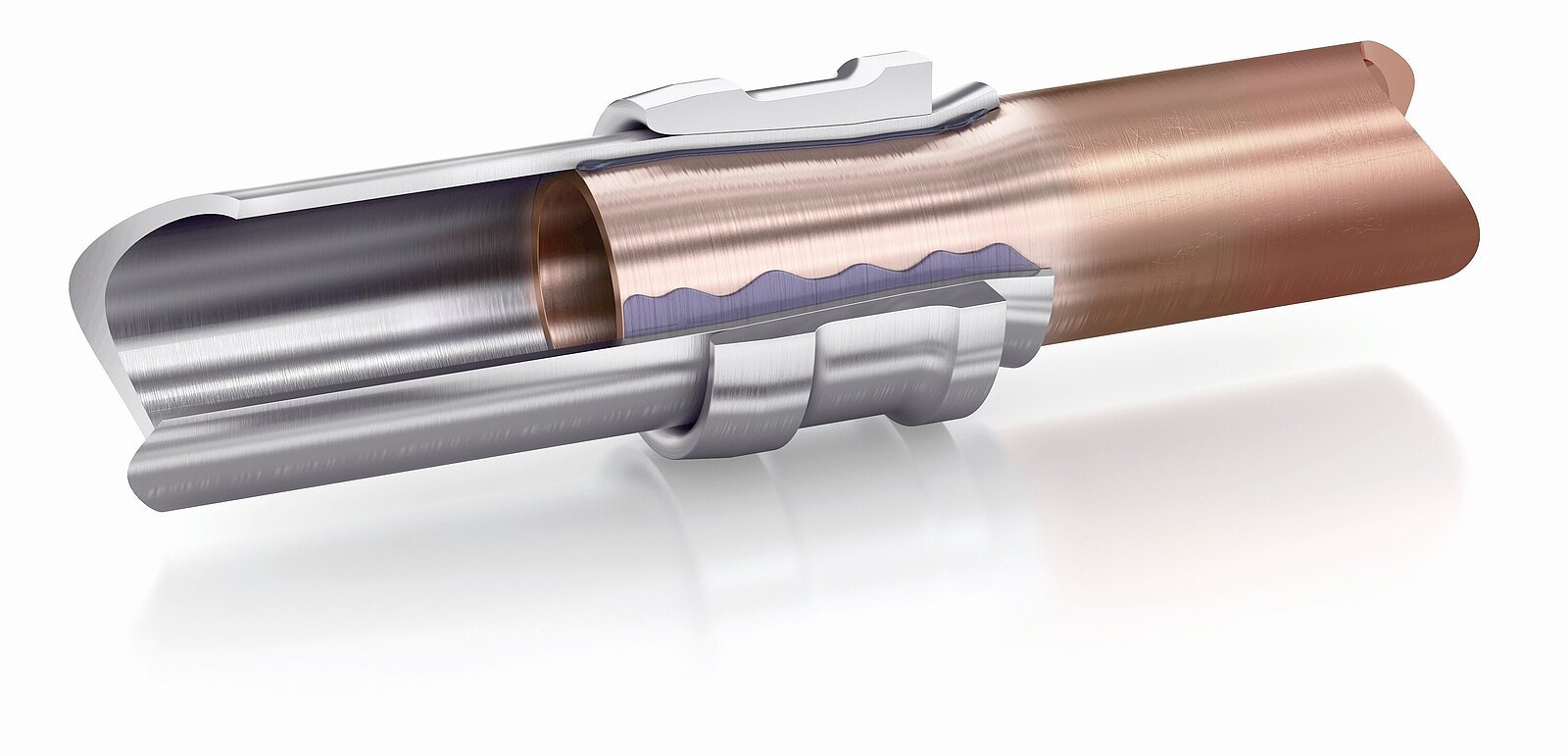

Functional Principle

Thanks to the conical inner contour of the LOKRING, the diameter of the outer tube is reduced during assembly to such an extent that the inner tube and the outer tube create a hermetically sealed metal-to-metal connection. The lifetime gas-tightness of the fitted connection is ensured by the state of permanent elastic pretension, which is produced by the radial forces of the LOKRING acting in the opposite direction to the connection between the outer tube and the inner tube.

For our various Single Ring applications, we have made dedicated Best Practice documents, which are available on request.

Lokring Single Ring Technical Specification

| Approvals | TÜV / UL (File SA12004) |

| Reference standards | EN 378-2 and ISO 14903 |

| Max. operating pressure Al | 25 bar (360 psi) with 5 times safety: 125 bar (1800 psi) |

| Max. operating pressure Cu | 40 bar (580 psi) with 5 times safety: 200 bar (2900 psi) |

| Max. operating pressure St | 50 bar (725 psi) with 5 times safety: 250 bar (3600 psi) |

| Admissible refrigerants | HFC, HC, not suitable for NH3 |

| Temperature range | -50°C up to 150°C (-58°F up to 302°F) |

| Tube diameter range | 1.6 mm up to 28 mm (1/16“ bis to 1 1/8“) |

| Min. tube wall thickness | 0.3 mm |

| Max. tube wall thickness | 1.5 mm |

| Max. roughness of the tube surface Rt | 40 Microns |

Via the following link you will find and overview of all our products for OEM applications.

Link to products

Sustainability

Since our tube connections are hermetically sealed, we can ensure that no climate damaging refrigerants leak into the environment. Furthermore, LOKRING makes the use of environmental friendly but flammable refrigerants (HC) safer and allows the use of CO2 (R744). Thus, by using LOKRING tube connections you make a contribution to the active protection of the environment.